SRM (Strech and Reduced) Pipes

Applications:

Compared to standard piping, SRM pipes are preferred due to their properties such as malleability and high resistance to corrosion, as well as machinability.

- Natural gas pipe line

- Oil pipe lines

- Onshore structures

- Construction Base

- Steel Struction Base

- General industrial applications

Standarts

Product Range

Outside Diameter: 21,3-613 mm (1/2"-2")

Thicknesses: 2,4-6 mm (0,095”-0,237”)

Lenght: 6 m

Steel Grades

API 5L PSL 1: Gr A, Gr B, X 42, X 46, X 52, X 56, X 60, X 65, X 70

API 5L PSL 2: Gr B, X42 , X46 , X52 , X56 , X60 , X65 , X70 , X80

ASTM A 53: Gr A, Gr B

ASTM A252: GRADE1, GRADE2, GRADE3

TS EN 10217-1: P 195 TR1, P 235 TR1, P 265 TR1, P 195 TR2, P 235 TR2, P 265 TR2

EN 10224: L 235, L 275, L 360

EN 10208 - 1/2: L 245NB, L 290NB, L 360NB

EN 10219 - 1/2: S 235, S 275, S 355

Manufacturing Standarts

EN-10217

EN 10224

DIN 1626

AWWA C-200

UNFA 49150

DIN 2460

UNI 6363

GOST 20295

EN 10208-2

ISO 3183

TS EN 10217-1

AWWA C200

BS 534

UNI 6363

TS EN 10224

BS 3601

TS EN 10219

AWWA C208

BS 534

Surface Preparation

ISO 8501 - 1, ISO 8502 - 3, ISO 8503 – 1

Coating

Polyethylene: AWWA C 215, DIN 30670, NFA 49710, TS EN 10288, UNI 9099

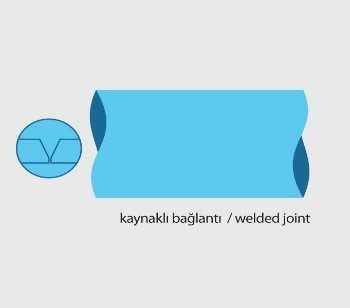

Pipe End

Welded Joint End

Special YTM plugs are used to protect the bevelled-end pipes.

Square End

Ends are beveled for stability of weld penetration ,to be ready for assembly of natural gas pipes.

Tests

Non Destructive Tests

- AUT Coil Lamination with 100% Coverage

- AUT Online Weld Inspection

- First Visual Inspection Manual

- Ultrasonic Inspection

- Hydrotest

- AUT Online Weld HAZ and Pipe End Lamination Inspection

- Digital X-Ray Weld Inspection

- Pipe End Magnetic Examination

- Magnetic Particle Inspection Final Visual and Dimensional Inspection

Destructive Tests

- Tensile Test Bending Test

- Charpy V Notch Impact Test

- Hardness Test

- Macro and Micro Metallographic

- Examination

- DWTT - Drop Weight Tear Test

- Chemical Analysis Crack Tip Opening

- Displacement (CTOD) Test

Test Certificates

- ISO 9712

- ISO 11484

- MTC according to EN10204/3.1