HFW Welded Pipes

Applications:

HFW welded pipes provides high precision dimensions and high capacity production value, Hsw welded pipes are using

- Oil, Natural Gas, Water lines

- Flammable & nonflammable liquid conveyance and distribution pipelines

- Steel structures for construction, general requirements

Standarts

Product Range

Outside Diameter: 2” – 16” / 60,3 mm – 406,4 mm

Wall Thickness: 0,083”-0,5” / 2,1mm-12,7mm

Unit Length: Max 16m

Material Grade

API 5L PSL 1: Gr A, Gr B, X 42, X 46, X 52, X 56, X 60, X 65, X 70

API 5L PSL 2: Gr B, X42 , X46 , X52 , X56 , X60 , X65 , X70 , X80

ASTM A 53: Gr A, Gr B

ASTM A252: GRADE1, GRADE2, GRADE3

Production Standarts

TS EN 10217-1(EN 10217-1): P 195 TR1, P 235 TR1, P 265 TR1, P 195 TR2, P 235 TR2, P 265 TR2

EN 10224: L 235, L 275, L 360

ISO3183-2015.2: L 245NB, L 290NB, L 360NB

GOST 20295: K34,K38,K42,K50,K52, and K55

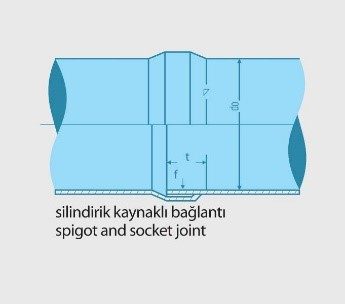

Pipe End

Welded Joint End

Spigot and Socket Joint End

Tests

Non Destructive Tests

- AUT Online Weld Inspection

- First Visual Inspection Manual

- Ultrasonic Inspection

- Hydrostatic testing

- Digital X-Ray Weld Inspection

- Pipe End Magnetic Examination

- Magnetic Particle Inspection Final Visual and Dimensional Inspection

Destructive Tests

- Tensile Test Bending Test

- Charpy V Notch Impact Test

- Hardness Test

- Macro and Micro Metallographic Examination

- DWTT - Drop Weight Tear Test

- Chemical Analysis Crack Tip Opening Displacement (CTOD) Test

Test Certificates

- ISO 9712

- ISO 11484

- MTC according to EN10204/3.1