Ductile Iron Pipes

Natural and/or manmade ground movements, is the main reason for water supply damages. Materials used in the production of pipes and fittings, have to be ductile, flexible and resistant to impacts in order to minimize the effect of these movements on networks.

Water distribution lines are high-cost investments. Therefore, features like life cycle cost, durability, low operation expenses, ease of assembling, maintenance and repair expenses ought to be considered as well as material unit price in the project designing and feasibility stages.

Ductile iron casting adds on tensile strength, impact resistance, and elongation abilities to the superior properties of metal casting which are high resistance to corrosion and abrasion, ease of machinability and fatigue strength.

Features

- Facilitating high resistance to loadings, pressure and vacuum with high tensile strength,

- Enabling high resistance to corrosion,

- Not requiring cathodic protection,

- Less operating cost since cast pipes have larger nominal diameter than polyethylene pipes.

- Being the best pipe in case of an earthquake, with its ability of resilience and resistance to impacts without deformation,

- Long product life, exceeding 100 years,

- Preserving the quality of water with healthy interior coating.

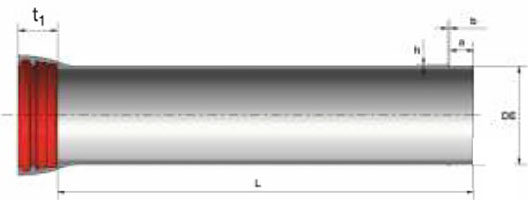

Dimensions: DN80 to DN2000

Thickeness: 6mm to 24,3mm

Material Properties

Minimum tensile strength Minimum elongation: 420 MPa

Maximum value of Brinell hardness: 230 HBW for centrifugally cast ironpipe, 250 HBW for fittings

Standarts

ISO 253: Ductile iron pipes, fittings, accessories and their joints

EN545: Ductile iron pipes, fittings, accessories and their joints for water pipelines

EN598: Ductile iron pipes, fittings, accessories and their joints for sewerage application

lnternal Linings and External Coatings

The entire pipes are coated with bitumen paint over zinc or epoxy paint over Zn-AL externally.

Although standard zinc and bitumen coating provide the necessary protection in many ground types, additional

polyethylene coating is recommended for excessively corrosive grounds.

The entire pipes are lined with a cement mortar layer internally, applied by centrifugal technique.

According to customer requirements, different types of linings and coatings can be applied.

Pipe End and Connection Types

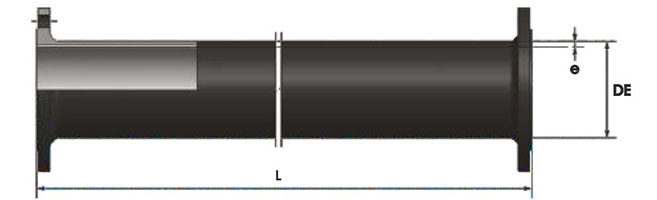

Flanged Type

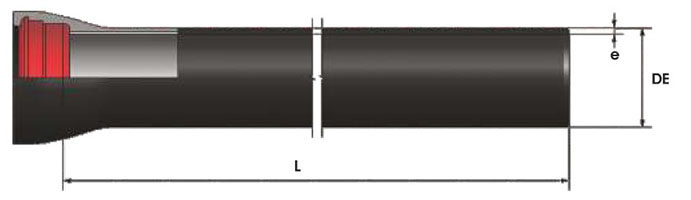

Standart Type

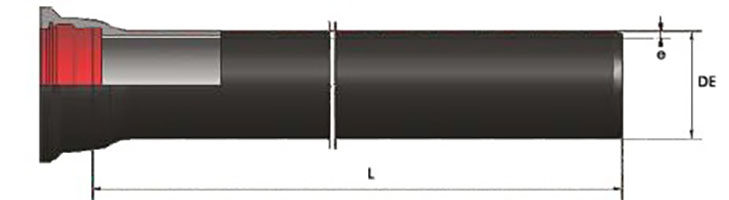

T Type Joint

Self Anchored Joint With Segments

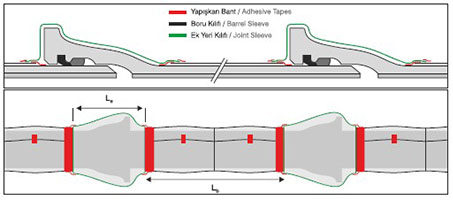

Polyethelene Sleeving