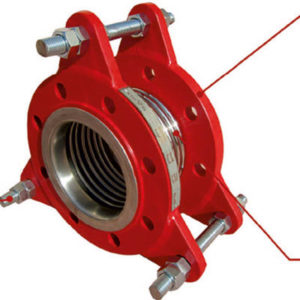

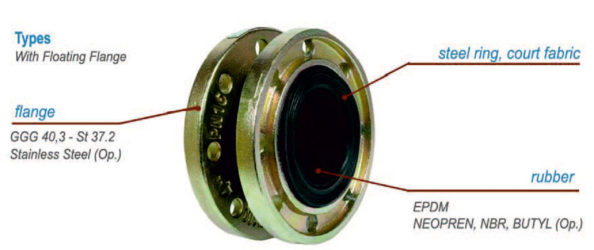

RUBBER EXPANSION JOINTS

This type rubber expansion joints are installed for vibration insulation. Its working pressure is 10 Bars but it cannot be deformed by 40 Bars peak pressure and 700 mm hg vacuum affect. YTMPipe Rubber Expansion Joint is best choice for plumbing system which works pressure up to 10 Bars.

Rubber expansion joint absorbs vibration and noise with its soft body which is resistant up to 90°C.

For more pressure and temperature, metal bellows expansion joints are better choice.

Other advantages of YTMPipe Rubber Expansion Joint are;

- rubber expansion joints provide excellent compensating features by their highly rated rubber bellows which is consisted of special synthetic rubber, steel wire and nylon braid fiber.

- Lateral and axial movements absorbing.

- Absorption of transverse movements.

- Peak force effect absorbing.

- Easily installation with its floating flanged according to working pressure.

- Joints and seals are not needed

Connection:

Floating flanged

Structure:

Synthetic neoprene with special cord reinforcement

Nominal Diameter:

DN 32(1 1/4") - DN 600 (24")

Working Pressure:

Working Pressure of standard YTMPipe Rubber Expansion Joint is 10 Bars maximum, working pressure is changed according to DN and temperature

Working Temperature:

- 10°C to 90°C

Application Area:

Plumbing systems

Pumps

Bellows

Ventilators

Vibration absorbers

Coolers

Ship Building

AC systems

Chemical, Petro-chemical and industrial systems

Power supplies

Iron and steel industries

Nautical industries

Paper industries

VIBRATION ABSORVER EXPANSION

Besides of compensating thermal expansions, the most important function of expansion joints is to solve the problems caused by the system vibration. Expansion joints are very effective especially on compensating the vibrations with high frequency and low oscillation.

Movement Absorption

Pump Connections

Expansion joints are used at the connections of the pump to the pipelines around the pump’s inlet and outlet. Fixed points right after the expansion joints are used to prevent the vibration through pipeline which is caused by the pump. Use of expansion joints for vibration absorbing is also useful to prevent the noise caused by the vibration.

Compressor Connections

In most cases, although the insulation applications, compressor movements cause vibration in the connected pipelines. Using expansion joint after the compressor absorbs the vibration caused by the compressor and provides ideal operation conditions for the system.

Advantages of Double Double Plied Vibration Absorbers

• They prevent damage to pumps result of the piping stress.

• They absorb vibration and noise in pump connections.

• They are installed easily and prevent the possible pump failures.

• They have a compact design that reduces the waste of space.

• The bellows and the braiding are manufactured with stainless steel material

• To provide required piping flexibility to the systems in order to maintain proper operating conditions.

• To protect equipment from stress due to misalignment.

DESIGN

Structure

Bellow Material: Stainless Steel AISI 321 (opt.304,316L,316TI,309) Double Plied

Connection Types: Fixed Flanged

Flange Material: Carbon Steel St.37.2 as standard, the material can be customized on request

Tie Rod Material: Carbon Steel St.37.2 as standard, the material can be customized on request

Carbon Steel: St.37.2 as standard, the material can be customized on request

Operation Conditions

Operating Temp.: -80°C/+600°C

Operating Pressure: PN 2,5/6/16/25/40/64

Nominal Diameters: DN25 (1”) - DN1000 (40”)